Defoamers

ServyecoChemicals | Natural Chemistry

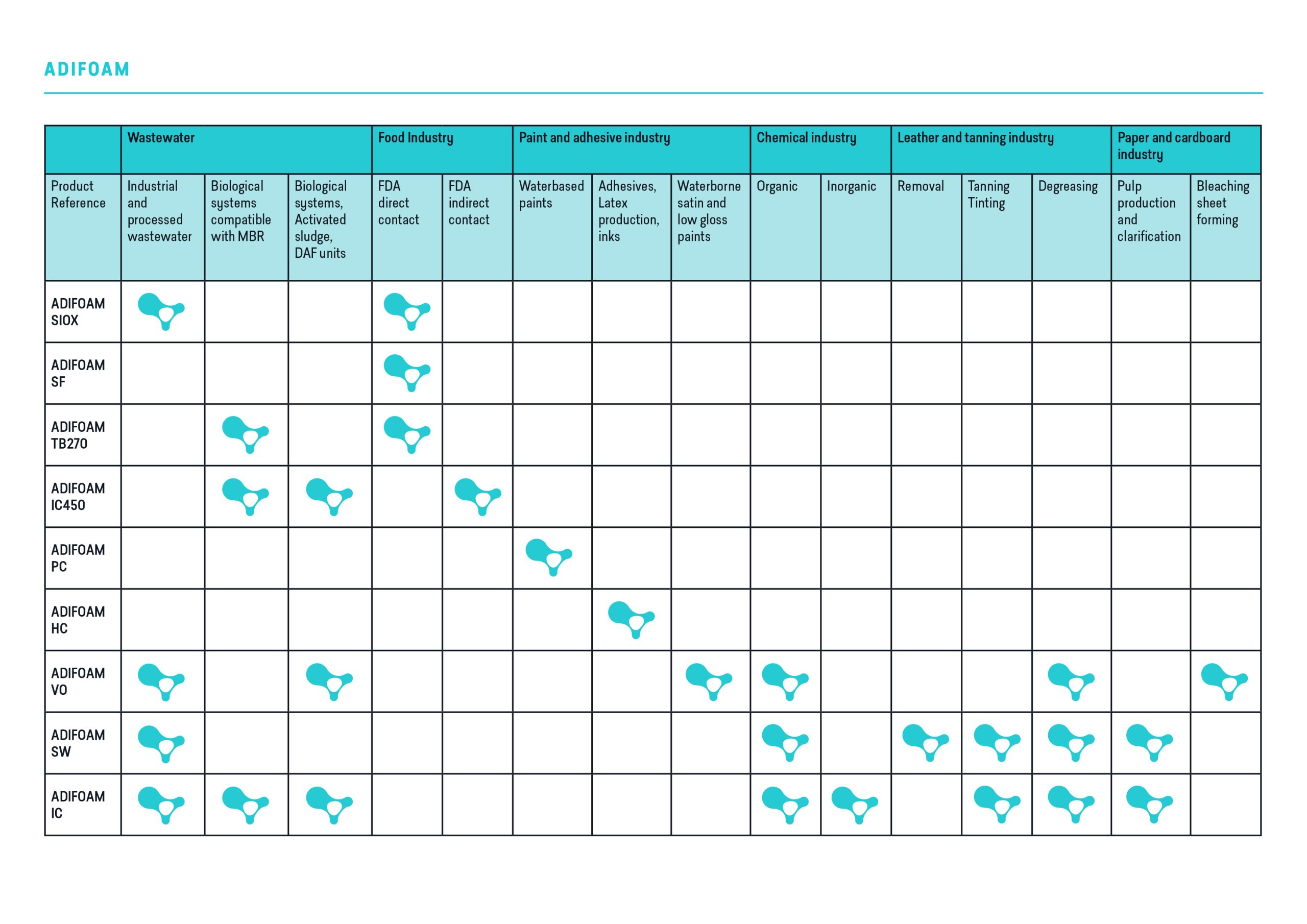

ADIFOAM

ADIFOAM defoamers are chemical additives manufactured by SERVYECO that reduce and eliminate foam in various industrial and water treatment applications.

WHAT THEY ARE AND HOW THEY WORK

A distinction can be made between defoamers and antifoaming agents. The former eliminate the foam that has already formed, while the latter prevent it from forming.

When a process generates foam, it can cause several problems, such as interfering with accurate metering, causing problems in pumping systems, reducing heat transfer, and preventing proper mixing. Defoamers counteract foaming by destabilising the foam structure. Once added to the system, defoamers migrate to the foam surface and alter the surface tension, causing the foam to collapse and disperse. The effectiveness of defoamers depends on factors such as the type, concentration and mixing conditions of each one.

The Chemistry and properties of defoamers

ADIFOAM defoamers are formulated using various chemical compounds such as silicone derivatives, mineral oils, fatty alcohols, and alkyl polyglycols. These compounds help to break the surface tension of the foam, causing it to collapse. The chemical properties and composition of each type of defoamer determine its effectiveness in controlling foam formation.

Adifoam active ingredients

Mineral oil based:

These defoamers are composed of an oil carrier, such as mineral or white oil, which does not dissolve in the foam generating environment. In addition, they include hydrophobic waxes and/or silicas to enhance their effectiveness. They are ideal for the removal of surface foam and are used in a variety of industries. They are useful in low surface tension systems.

ADIFOAM IC / HC.

Vegetable oil based:

These contain various types of oils and waxes dispersed in an aqueous medium. The oils can be of vegetable origin, while the waxes can be long chain fatty alcohols, fatty acid soaps or esters. Their main function is to act as degassers, releasing air trapped in liquids. They are environmentally friendly and cost-effective. They are high performance products at temperatures between 5 – 90ºC which are also FDA by direct contact.

ADIFOAM SF / VO.

Silicone-based:

These are composed of polymers with silicon structures, such as polydimethylsiloxane. They can be found in oil or aqueous emulsion form. They are high strength defoamers, efficient in both the removal of surface foam and the release of trapped air. They are suitable in non-aqueous foam generating systems, such as crude oil and its refinery. These defoamers have better stability under a variety of conditions. Widely used in the food industry.

ADIFOAM SIOX / PC / SW.

EO/PO based:

These defoamers contain copolymers of polyethylene glycol (EO) and polypropylene glycol (PO), and can be supplied as oils, aqueous solutions, or water-based emulsions. They have excellent dispersing properties and are ideal for solving sedimentation problems.

ADIFOAM TB.

Application of defoamers by sector

Wastewater treatment

Our ADIFOAM products can be used in various applications in the wastewater treatment sector, whether industrial or urban effluents. By eliminating foaming operating costs can be reduced, water quality improved, technical stoppages due to clogging of pumps and circuits can be avoided, as can fouling of control equipment, or dragging of suspended solids in the treated water.

Areas of application:

Physico-chemical treatments

Anaerobic systems

Aerated lagoons

Activated sludge systems

Biological nutrient removal (BNR)

Membrane bioreactor (MBR)

Food industry

In the food industry, foaming can be a major problem during processing, packaging, and storage. Defoamers are commonly used to prevent foam from affecting the quality, safety, and shelf life of food products. They help prevent foaming during mixing, stirring, or boiling during processing.

Applications:

- Vegetable washing

- Frozen vegetable processing

- Food processing

- Slaughterhouses: blanching line, equipment cleaning, meat processing

- Container cleaning

Recommended products:

ADIFOAM SIOX, ADIFOAM SF, ADIFOAM TB

ADIFOAM IC,

Paint and adhesive industry

ADIFOAM defoamers play a crucial role in the production of paints and coatings. During paint manufacturing, various ingredients are combined to create a homogeneous mixture. However, this process can often generate air bubbles and foam which, if left unchecked, can result in an uneven and poor-quality finish.

Applications:

- Waterborne satin paints

- Adhesives

- Latex production

- Varnishes

- Low gloss water-based paints

- Inks

Recommended products:

ADIFOAM PC, ADIFOAM HC, ADIFOAM VO

Chemical industry

In the chemical industry we use our ADIFOAM defoamers to control foaming during manufacturing, especially in polymerisation reactions. Excessive foaming can lead to poor quality products, slow production rates and equipment damage. Our silicone defoamers are particularly effective in the chemical industry and offer superior foam control, stability and compatibility properties.

Applications:

Polymerisation reactions

Resin manufacturing

Lubricant manufacture

Coating manufacture

Dissolving of cutting oils and cutting oils

Mixing with alkaline degreasers

Manufacture of surfactants

Recommended products:

ADIFOAM SW, ADIFOAM VO, ADIFOAM IC

Leather and tanning industry

In the leather and tanning industry, we use doses of ADIFOAM defoamers to improve the uniformity and the final finish of the pieces. They are used in different stages of the process, de-foaming, de-sizing, and dyeing, improving the performance of each one and avoiding the problems generated by foams.

Recommended products:

ADIFOAM SW, ADIFOAM IC, ADIFOAM VO

Paper and cardboard industry

Foams are produced at various stages during paper and cardboard production. Our defoamers are applied to improve the quality and colour of the paper and to obtain a final product with the desired properties.

Recommended products:

ADIFOAM SW, ADIFOAM VO, ADIFOAM IC

Comparative table by sector and application